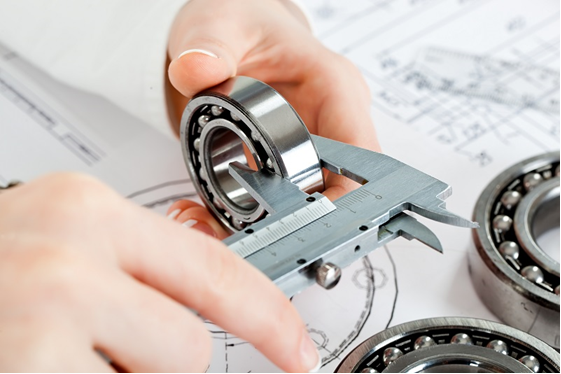

Contrary to machining without CNC programmed capability, tool making has several advantages. Cycle durations can be shortened, finishes can be enhanced, and numerous processes can be finished simultaneously, which can enhance consistency and quality. When precision and complexity are necessary, medium and large volume needs are well suited for it.

These tool making procedures have several uses in a variety of industries, including medical, aerospace, automotive, oil and gas, hydraulic systems, and weapons, among others. CNC machines can work with a wide range of materials, including metal, plastic, glass, composites, and wood.

CNC turning and lathe tools

The capacity to rotate (turn) materials during milling is a distinguishing feature of CNC lathes and turning machines. These machines feed their cutting tools around the revolving bar stock in a linear motion, removing material from the circumferential until the required size (and feature) is obtained.

With CNC Swiss lathes, the material bar rotates and enters the machine by sliding axially via a guide bushing (a retaining mechanism). As the tooling shapes the features of the part (resulting in better/tighter tolerances), this offers much better support for the material.

Drilled holes, boreholes, broaches, smacked down holes, slots, tapping, tapers, and threads are just a few of the internal and exterior characteristics that CNC lathes and spinning machines may add to the component. Screws, bolts, shafts, poppets, and other components are manufactured on CNC lathes and spinning centers.

CNC Laser Equipment

In order to accurately cut, slice, or engrave objects, CNC laser machines employ a pointed cutter with a highly concentrated laser beam for tool making. A cut is made in the material as a result of the laser heating it to the point where it melts or vaporizes.

Usually, the substance is hereditarily, and a precise cut is made by moving the laser beam backwards and forward over the material. Compared to traditional cutting equipment (lathes, turning centers, mills), this approach may create a larger variety of patterns and frequently results in cuts and/or edges that do not need extra finishing procedures.

CNC Milling Equipment

The capacity of CNC milling machines to rotate wire cutters while retaining the material workpiece or block motionless is one of these machines’ distinguishing features.

They are capable of creating a variety of forms, such as face-milled features (thin, flat surfaces and cavities in the workpiece) and peripheral-milled features (deep cavities such as slots and threads). The forms and characteristics of components made on CNC tool making machines are generally square or rectangular.

Plasma CNC cutting devices

Materials are sliced using CNC plasma cutting devices as well. However, they carry out this procedure with the aid of a computer-controlled, high-powered plasma (electronically ionized gas) torch. Plasma torches may reach temperatures of up to 50,000 degrees Fahrenheit and perform similarly to a portable, gas-powered welding torch. To cut the material, the laser torch burns through the workpiece.

Anytime CNC plasma cutting is used, the material getting cut must be good conductors of electricity as a prerequisite. Steel, alloy steel, aluminum, brass, and copper are typical building materials.

Electrical Discharge Machines using CNC (EDM)

A CNC electric discharge machine (EDM) shapes materials into the required shape using carefully regulated electrical sparks. It is also known as wire burning, dies sinking, spark machining, and spark erosion. The machine is designed to create an electrostatic force from the electrode wire that generates a great deal of heat, and a component is positioned underneath the electrode wire. To generate the desired form or feature, the metal is vaporized or washed away with liquid.

In the process of making tool making, creating accurate micro-holes, slots, tapered, or angled features are where EDM is most frequently employed.