Last Updated on April 7, 2024 by Umer Malik

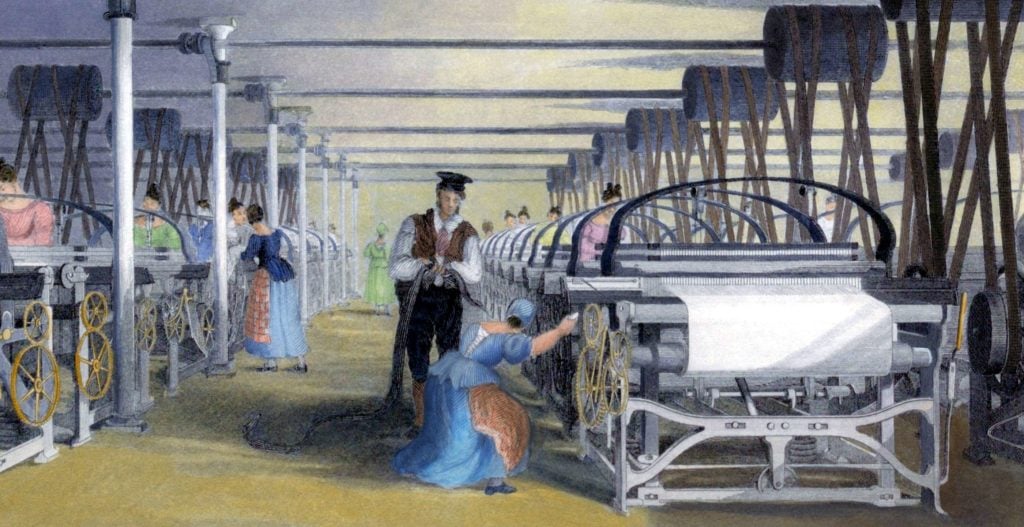

The manufacturing process started taking a u-turn from about the period 1760 to between 1820 and 1840. This time made drastic changes in everyone’s lives as hand production has converted to machines and chemical manufacturing. Moreover, the iron production process was also introduced. Textiles were a major part of the Industrial revolution in terms of employment, the value of the output, and the capital invested.

Pre-Industrial functioning of the Textile Industry

Earlier in the 17th century, the manufacturing of fabrics has on a very limited scale, as workers used to work in their own spaces and with fewer resources. Some of the clothes were made for the people living in the same region and a large amount was exported. Later on, in the 18th-century artisans started inventing ways to become more productive. For instance, spinning and weaving were done in households for domestic consumption. During the off-season, farmers’ wives used to do spinning and men did the weaving part.

Evolution of the Industrial Revolution

The textile industry was the first sector that used modern production methods. Most of the technological innovations were British and the industrial revolution too started in Great Britain. It was a major turning point as it affected all aspects of life in some or the other way. For instance, the average income and population began growing. And because of this, around the 19th and 20th centuries, a greater impact was there on the general population and their standard of living. As it too started to increase consistently, because of the expansion of roads, canals, railways, overall transport, and many more.

Textile Machinery

There have been several inventions in textile machinery that occurred in a relatively short period during the Industrial Revolution. Which somehow or the other have benefitted the whole society. Let’s have a look at it with the help of the timeline.

In the 17th Century Textile Industry

1733, | The Flying shuttle was invented by John Kay: which was an improvement to looms that helped weavers to weave faster. |

1742 | It was the first time when Cotton mills were opened in England. |

1764 | James Hargreaves invented the Spinning jenny which was the first machine that improved the spinning wheel device. |

1764 | Richard Arkwright invented the Water frame which was the first powered textile machine. |

1769 | Arkwright had its patent on the Water frame. |

1770 | Hargreaves got its patent on the Spinning Jenny. |

1773 | It was the first time that all cotton textiles were produced in factories. |

1779 | To have greater control over the weaving process, Crompton invented the spinning mule. |

1785 | William Horrocks who is known for his invention of the variable speed button in 1813, improved the power loom which was patented by a cartwright. |

1787 | This year cotton goods production had increased by 10-fold since 1770. |

1789 | Textile machinery design was brought by Samuel Slater to the US. |

1790 | The first steam-powered textile factory in Nottingham, England was built by Arkwright. |

1792 | Eli Whitney invented the cotton gin which is the machine that automated the separation of cottonseed from the short-staple cotton fiber. |

In the 18th Century Textile Industry

1804, | Joseph Marie Jacquard invented the Jacquard Loom, which weaved complex designs. Moreover, Jacquard invented a way that automatically controls the warp and weft threads on a silk loom. With the method of recording patterns of holes in a string of cards. |

1813 | The Speed button variable was invented by William Horrocks to have an improved power loom. |

In 1856 | The first Synthetic dyes were invented by William Perkin. |

A brief about Horse Power

Back in the time, cotton mills in the US functions with the help of horse-powered methods. And the first ill which used this method was Beverly Cotton Manufactory, in Massachusetts. In 1788 the equipment for the mill was complete, consisting of a spinning jenny, a carding machine, a wrapping machine, and other tools. To have a better functioning the location of the mills was finalized and has shifted to rural outsets of North Beverly. However, it hasn’t changed to have mass production. Instead, the primary concern shift that the freshwater can be used to upkeep the horses, cleaning of equipment, and more. Moreover, another reason was to hide from competitors so that no one can steal their designs.

The textile industry from many eras is changing itself to have comfort for people to have mass production and less labor work. And it is still evolving, in terms of technology.